Leveling Feet: The Foundation of Stability and Performance

Over the past three decades, the leveling foot has evolved from a simple accessory into a core component of modern machine assembly. When combined with other high-performance technical products, it becomes part of a complete solution that delivers real value — both to manufacturers and to end users.

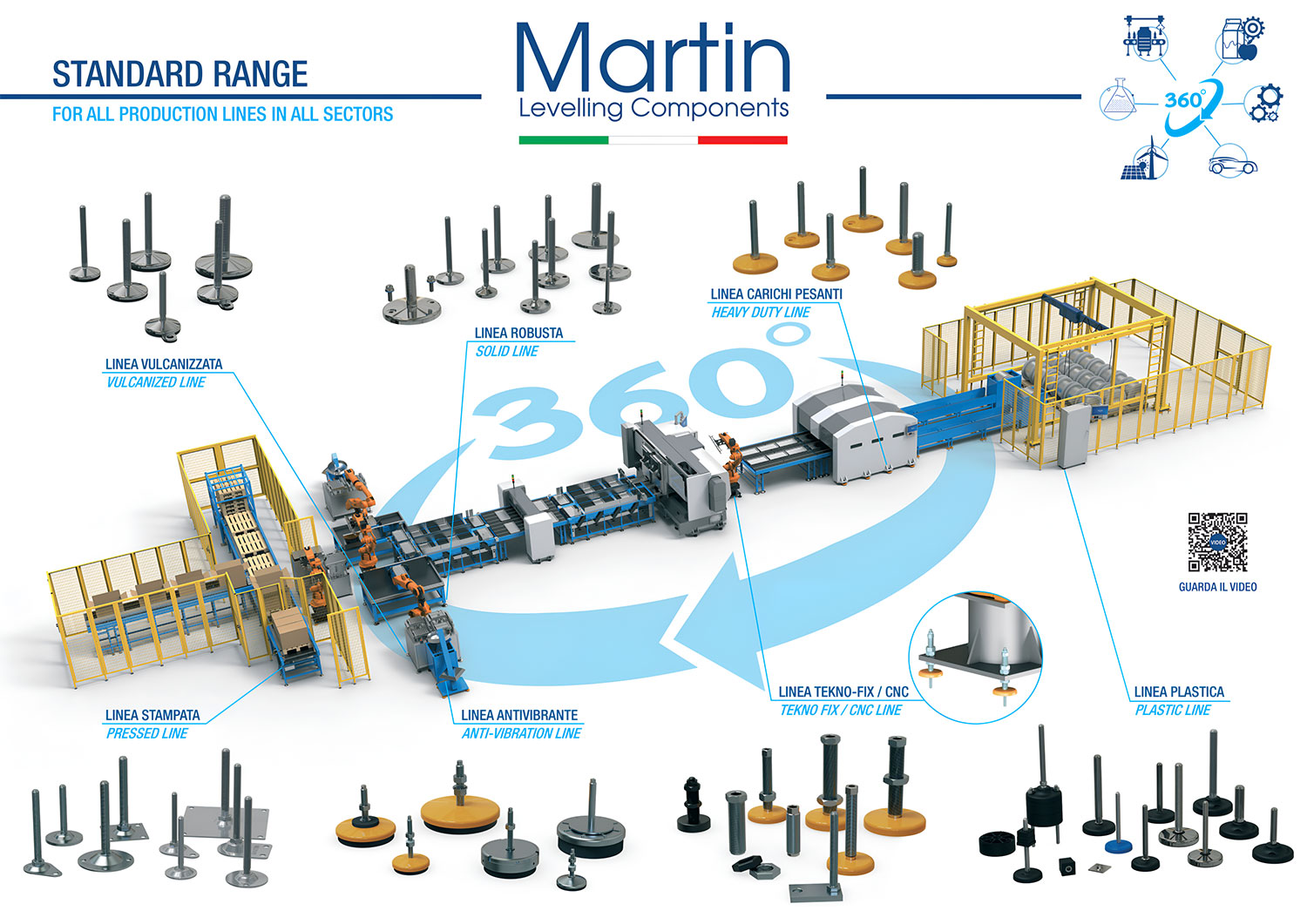

Designed to provide stability, precision, and support, leveling feet are used across an extraordinary range of industries. Virtually every type of machine can be equipped with either castors and wheels or adjustable feet, depending on operational needs. From the latest CNC machines — such as lathes, milling machines, machining centers, and laser or waterjet cutters — to systems for wood, textile, glass, ceramics, paper, and tobacco processing, the applications are endless.

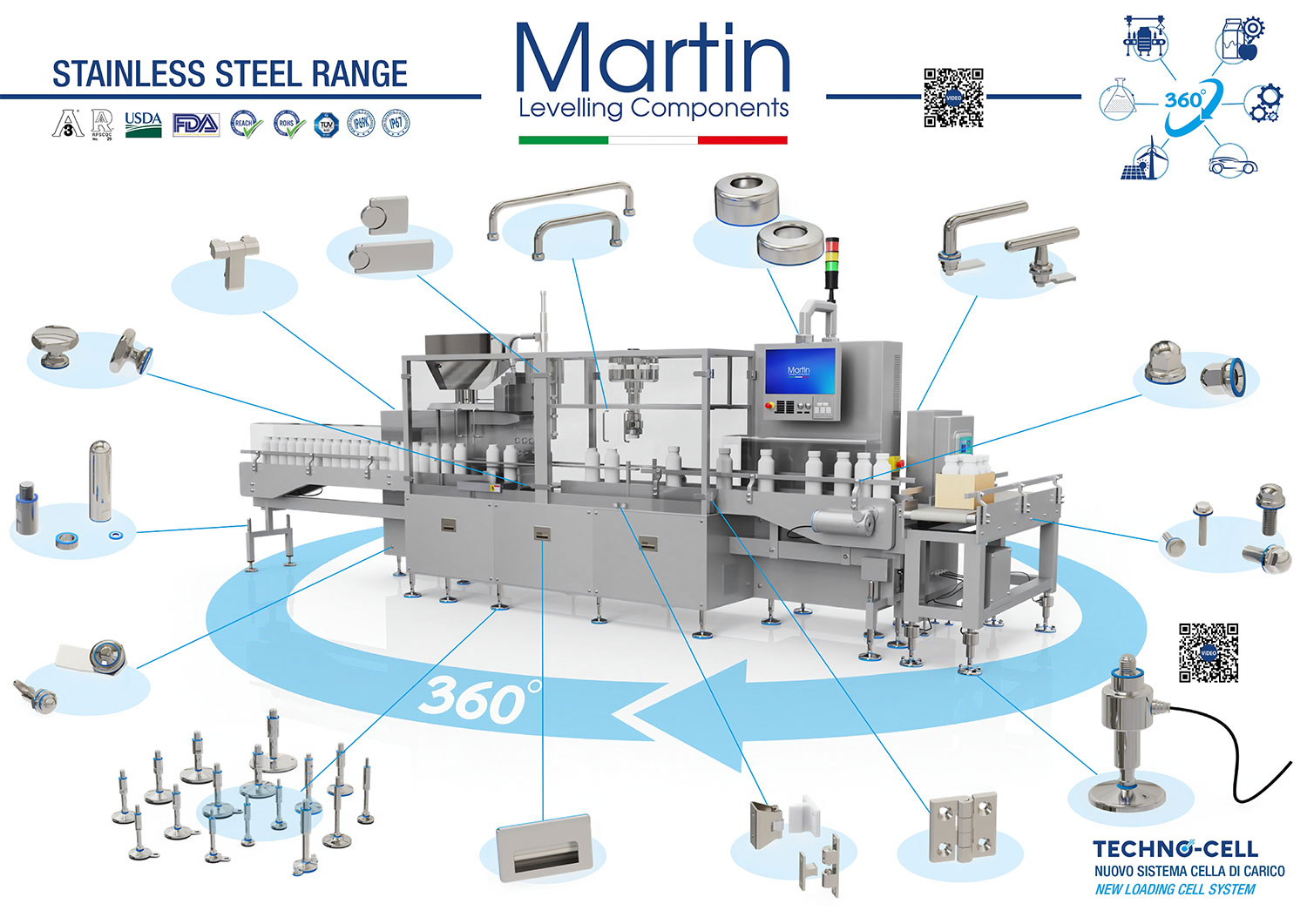

They also play a vital role in sectors where hygiene and durability are non-negotiable, including food processing, packaging, bottling, meat, and dairy industries, as well as in the chemical, pharmaceutical, and cosmetics fields. Beyond that, military, solar, and renewable energy companies rely on leveling feet to ensure stable, reliable performance under the most demanding conditions.

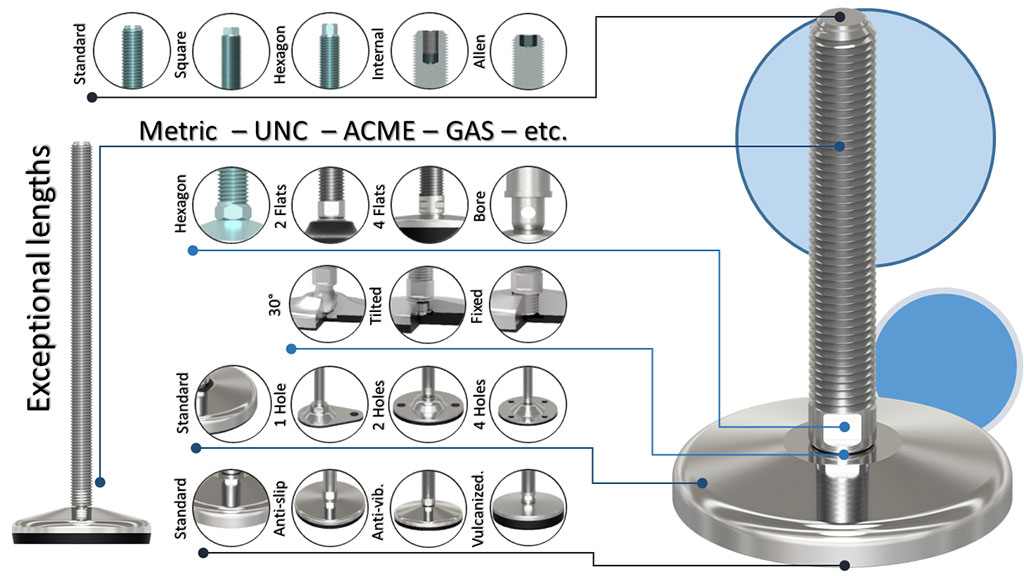

Although technically simple, the leveling foot must meet a wide variety of industrial demands. Requirements for high-performance, REACH- and RoHS-compliant materials, precision engineering, and refined design make this product far from ordinary.

Sourcing top-quality components that are both affordable and immediately available can be a challenge. The countless variations of a single model make stock management complex — yet experience shows that this investment pays off. In today’s market, speed of delivery and reliability often make the difference, even more than price.

Leveling feet also find ideal applications in conveyor systems, palletizers, robotic arms, household appliances, shelving, scales, presses, and electrical cabinets — proving their versatility across industries.

Our long-standing experience, together with that of our Italian and international partners, has taught us a key lesson: the best results come from offering leveling feet as part of a complete product package, not as stand-alone components.

Integrating them with power transmission products — such as bearings, gearboxes, gearmotors, belts, chains, and linear guides — creates an unbeatable combination for automation and motion control.

Likewise, pairing leveling feet with standard machine elements — handles, hinges, knobs, latches, and other structural components — delivers added functionality and design consistency.

Finally, anti-vibration solutions such as buffers, silent blocks, and shock absorbers form a natural complement to leveling feet. Though vibration control requires specific expertise, it remains closely linked to support technology.

Within this segment, Martin offers a complete range of high-quality products designed to minimize vibration, maximize stability, and enhance performance — helping our customers expand their product offering and strengthen their position in the market.